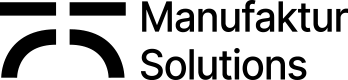

VIBRATORY FLUID BED

DRYER

A Vibro Fluidized bed dryer operates on the principle of vibration and fluidization. It combines the advantages of both fluidized bed drying and vibrational conveying.

Learn More About VFBD

What is a Vibratory Fluid Bed Dryer?

A vibratory fluid bed dryer is an enhancement in fluid bed drying equipment that combines fluidization with mechanical vibration to efficiently dry particulate materials. The hot air or gas fluidizes the particles while vibrations ensure even distribution and prevent clumping, leading to uniform drying and enhanced processing efficiency.

Working Principle of a Vibratory Fluid Bed Dryer

A uniform quantity of fermented tea is continuously passed through the uniform feed distributor which also acts as a ball breaker. Within the chamber, a perforated plate positioned at the base facilitates the process. Vibrators generate oscillations that induce fluidization of the material bed. Concurrently, hot air ascends through the perforations, creating an upward airflow that permeates the material bed. This airflow establishes a fluidized state wherein particles exhibit fluid-like behaviour. As the hot air traverses the fluidized bed, it transfers heat to the moist material particles, initiating evaporation and facilitating efficient drying. The evaporated moisture is carried away by the airflow. Upon achieving the desired moisture content, the material is discharged from the dryer chamber, prepared for subsequent processing.

Salient Features

- Robust and Insulated construction to prevent heat loss

- Hygienic construction

- Independent suspension of Plenum Chamber

- Control panel with temperature indicators

- Stainless steel agitator

- Air balance mechanism

Advantages

- Uniform Drying: The combination of fluidization and vibration ensures even drying of particles, reducing the risk of uneven moisture content and hot spots.

- Enhanced Efficiency: Improved heat and mass transfer rates due to efficient particle movement and mixing, leading to faster drying times and reduced energy consumption.

- Gentle Handling: The vibrating action prevents excessive agitation, minimizing damage to fragile or sensitive materials.

- Consistent Quality: Precise control over temperature, airflow, and vibration helps achieve consistent product quality and moisture content.

- Reduced Product Clumping: Vibration prevents particles from sticking together, ensuring free-flowing and non-clumped dried material.

- Scalability: Available in various sizes, from laboratory to industrial scale, allowing flexibility to meet different production needs.

Specifications

- Variable frequency drive to control the vibration

- Fuel type that can be used are Coal, Gas, Oil and Wood

- Air directional louvers fitted within plenum chamber

- Two-stage temperature drying and air mixing chamber

- Dryers of various capacities are available

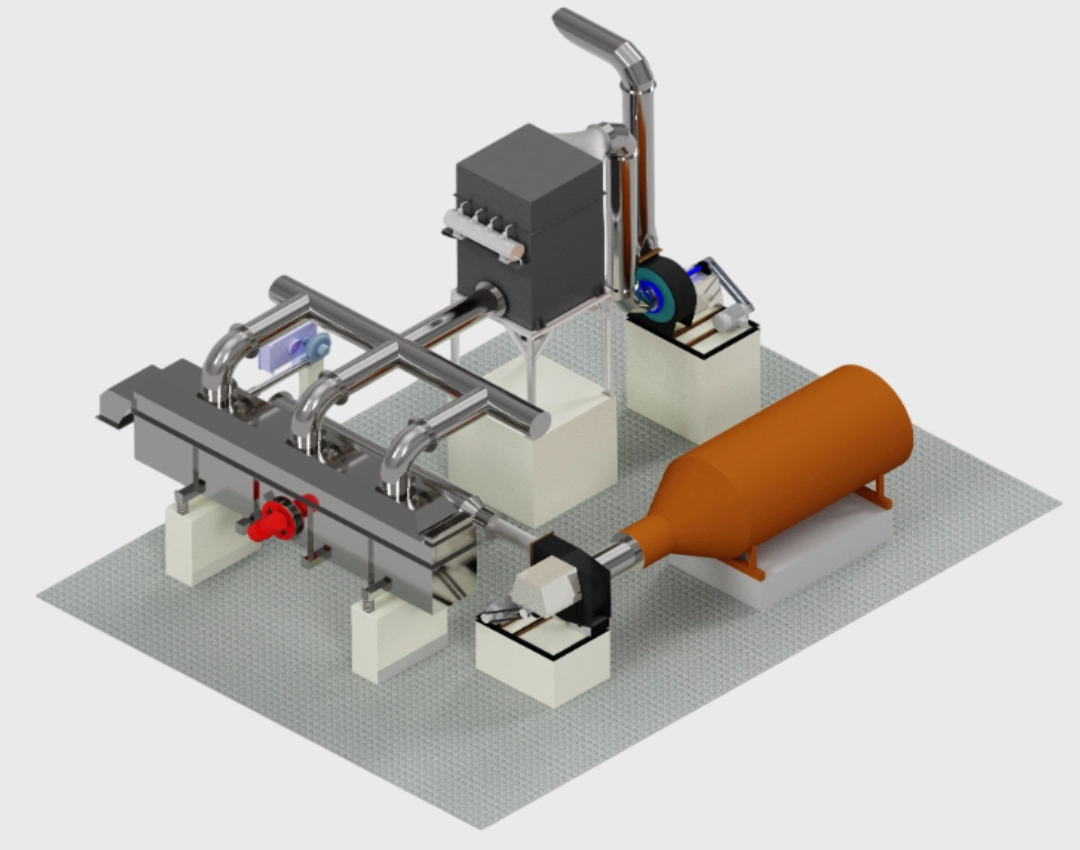

Process Flow Diagram

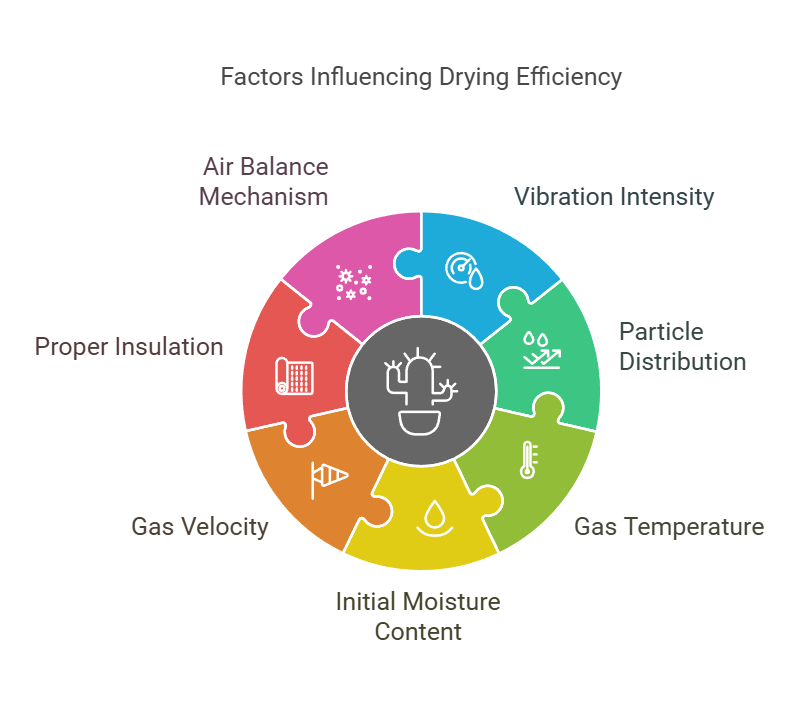

Factors Affecting Drying Rate

Application

Pharmaceuticals

Chemical

Packaged Food

Carbon Black

Plastics and Polymers

Mining Industry

Have Questions ?