Aeris Multi Stage Dryer

In MSD, Aerodynamic air plenum design distributes airflow evenly. With our multistage multi-pass technology, consumers with space constraints can boost their capacity up to 3 times and maximize productivity.

Learn More About Aeris

An Advanced Drying Solution

In today’s industrial landscape, dried products play a critical role across multiple sectors, from food processing to pharmaceutical manufacturing. The key to efficient production lies in advanced drying technologies that can deliver consistent, high-quality results. Enter the GEM’S AERIS Multi-Stage Dryer (MSD) – a cutting-edge drying solution designed to meet the diverse and demanding requirements of modern industrial applications.

What is a Multi-Stage Dryer?

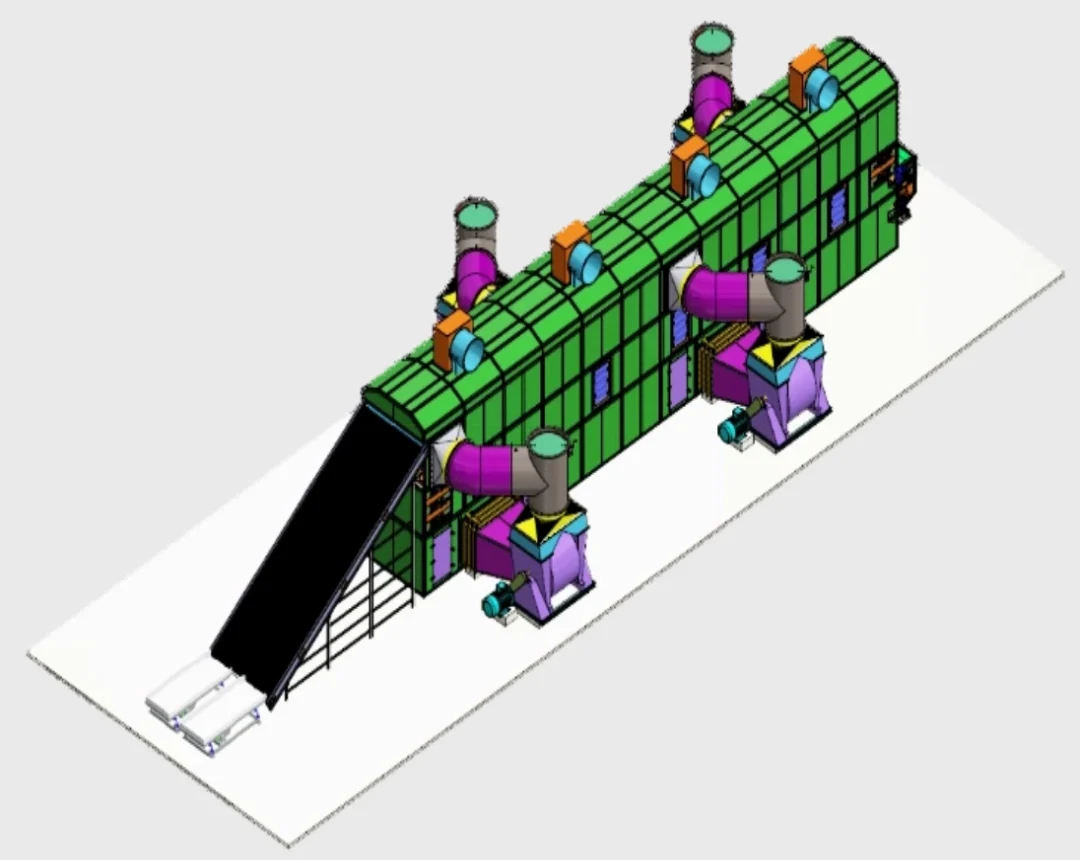

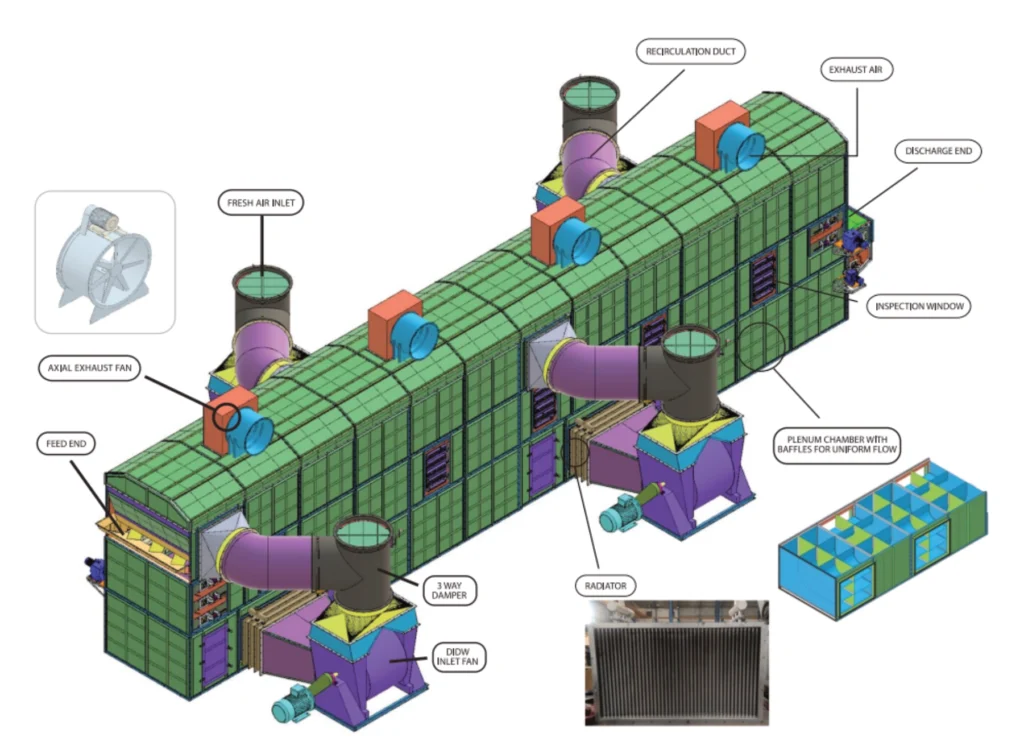

MSD or Multi-stage Dryer are one of those machines on which the drying industry employs extensively. The beauty of Multi-stage Dryer can be described in its ability to produce a variety in large quantities in a compact design. It operates by passing the material over a series of conveyor belts or mesh screens in multiple stages or compartments, where it is exposed to heated air or gas.

Working Principle of a Multi-Stage Dryer

In a Multi-stage dryer, materials progress through successive drying phases, each progressively reducing moisture content. Initially, elevated temperatures and airflow remove surface moisture. Subsequent stages adjust conditions to sustain drying while minimizing potential damage. In the final stage, further drying occurs to achieve the target moisture level. Material transfer between stages is facilitated by mechanisms like belt and chain or tray and chain systems to ensure continuous processing flow.

Salient Features

- A highly efficient air recirculation system

- Refined design

- Chain and Belt monitoring systems

- Fine management

- Belts & Conveyors

- Different type of heat source can be incorporated like flue gas, steam and thermic fluid

Advantages

- Unparalleled Moisture Uniformity: Longer retention time with the multistage dryer leads to more efficient and uniform drying. Even airflow through an aerodynamically designed plenum chamber provides the most consistent moisture uniformity.

- Maximum Productivity: With our multistage multi-pass technology, consumer with space constraints can boost their capacity up to 3 times and maximize productivity. Due to substantial core flexibility, maximized outputs are guaranteed for all types of products.

- Energy Efficient Performance: The dryer is highly efficient and utilizes limited power. Effective and efficient exhaust and air blowers make optimal use of energy as well as lower noise during operation.

- Superior Process Controls: The drying system adds a new degree of control, automation, and quality to the processing of all kinds of food products. Engineers engage with you to develop and manufacture equipment that is tailored to your needs and as cost economically as possible in order to improve overall productivity.

Types of Multi-Stage Dryer

Horizontal Dryer

- Single Stage Single Conveyor Dryer

- 2 Stage Single Conveyor Dryer

- 3 Stage Single Conveyor Dryer

- Includes integrated cooling section and vibration device for easy product unloading

Vertical Dryer

- Ideal for limited floor space or extended drying processes

- 3 Stage 3 Pass MSD

- 3 Stage 6 Pass MSD

- Multizone Variable Temperature MSD

Specifications

- The drying area up to 360 m² has been successfully designed and tested

- Wire mesh drying belt / SS perforated (Apron) tray

- Modular designed construction with galvanized mild steel / stainless steel with rock wool insulation for high heat resistance

- Inspection window provided at specific points with heat resistant toughened glass

- PLC with HMI display panel with internet connectivity

- Air knife/ rotary brush/ water jets to clean belt / tray

- Sensors (Feed height sensors and Limit switch)

Process Flow Diagram

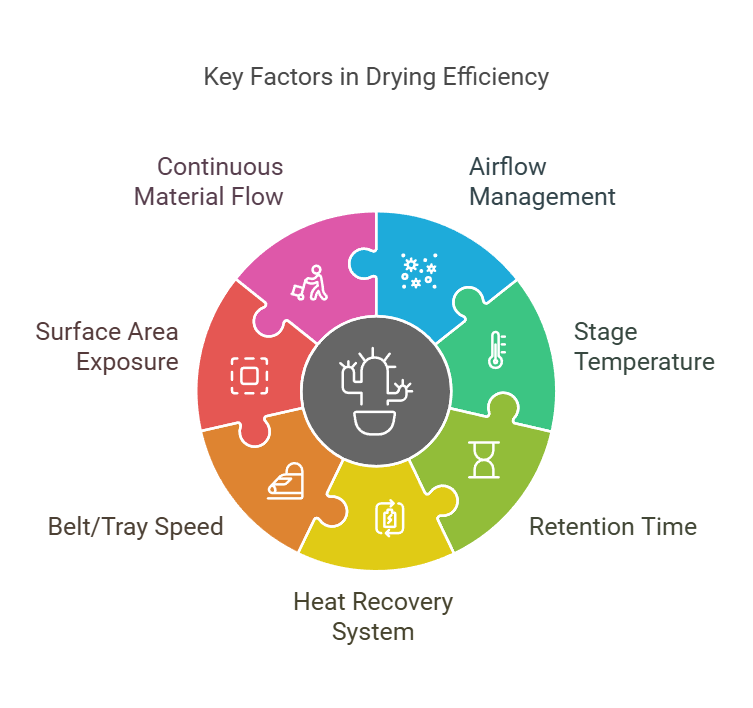

Factors Affecting Drying Efficiency

Applications

Chips

Dry Fruits

Minerals

Casava

Super Absorbent Polymer

Coal and Charcoal

Have Questions ?