CONTINUOUS THIN FILM

DRYER

A Fourth-Generation drying technology for best quality with better efficiency.

Also known as Refractance

Window Dryer.

What is a Continuous Thin Film Dryer?

Refractance Window/Continuous thin film drying is a safe way to dehydrate fresh whole foods. It gently extracts water from our foods while preserving vitamins, minerals, and micronutrients.

In a Refractance Window Dryer, the food is not directly exposed to extreme hot or cold temperatures during drying. It is instead based on the transfer of thermal energy from warm water to food. This continues until a precise point of dehydration is reached, at which point the drying process automatically stops.

Working Principle of a Continuous Thin Film Dryer

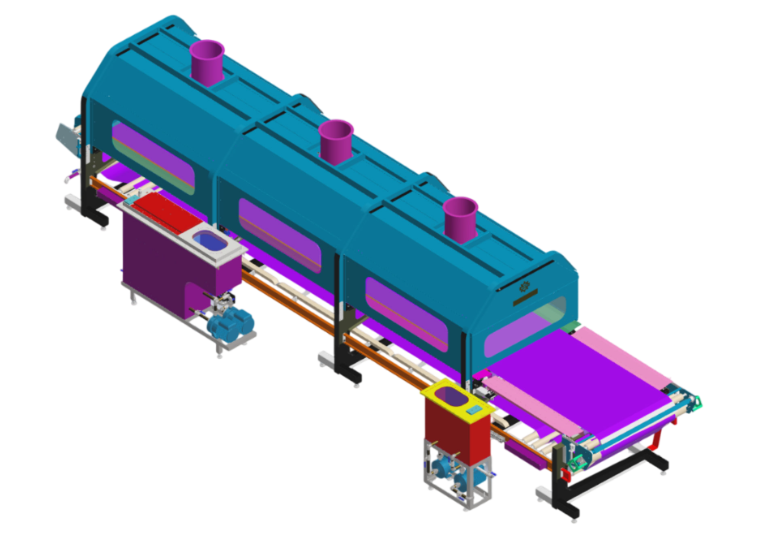

In Continuous Thin Film Drying (CTFD), products are conveyed over transparent membranes heated by circulating hot water. This gentle dehydration technique is designed to preserve the quality of foods, making it especially appropriate for heat-sensitive materials such as fruits and vegetables. By operating at low product temperatures (70°C), CTFD gently dries food products while maintaining essential nutrients like vitamins and colour, and preserving active aromatic and pigment compounds, thereby enhancing aroma and flavour retention. Additionally, it is environmentally friendly, as it does not produce exhaust dust.

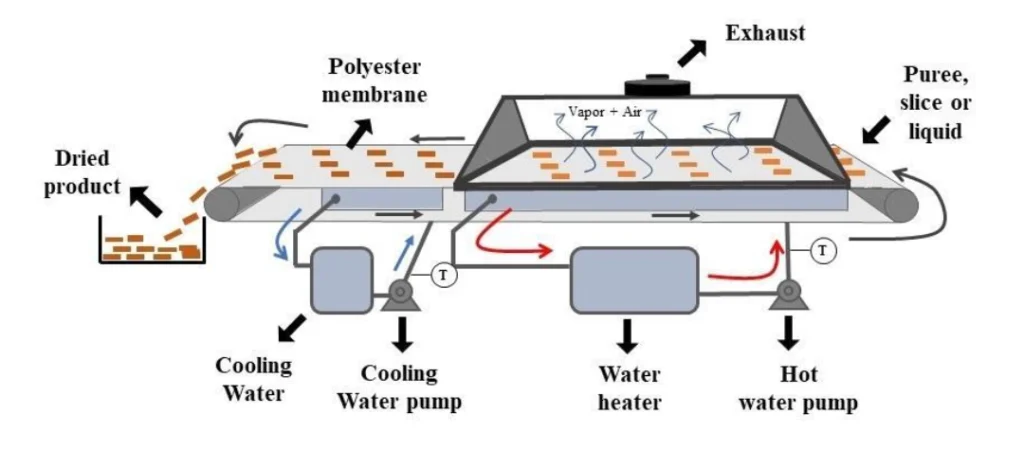

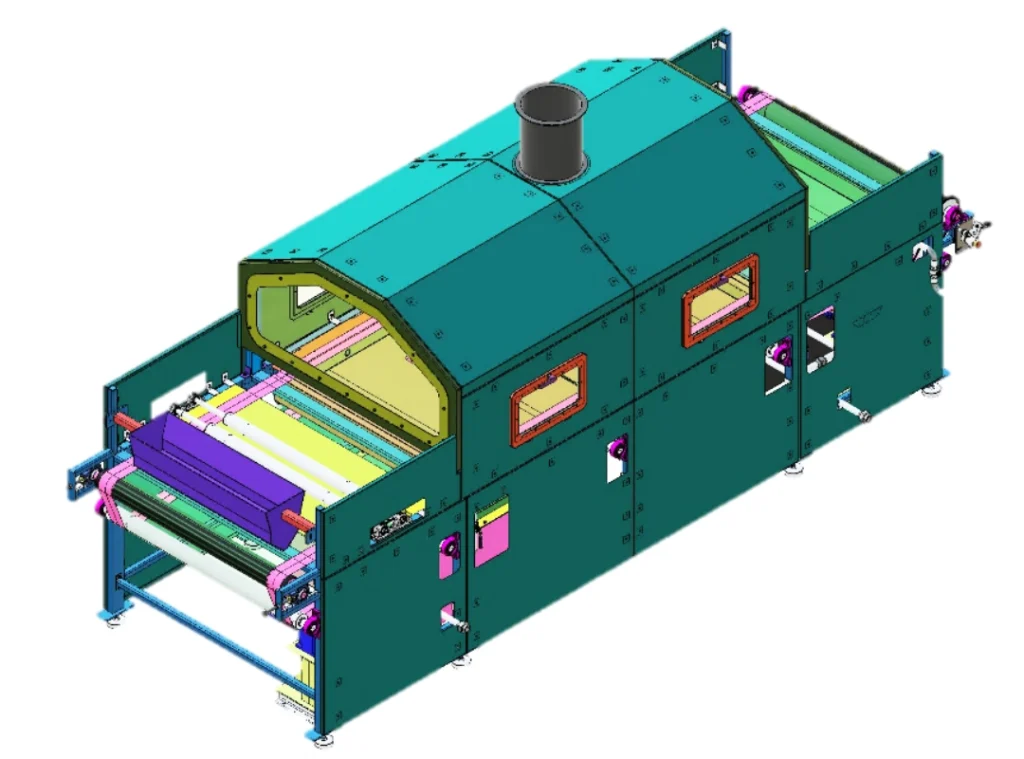

Pilot Scale Model

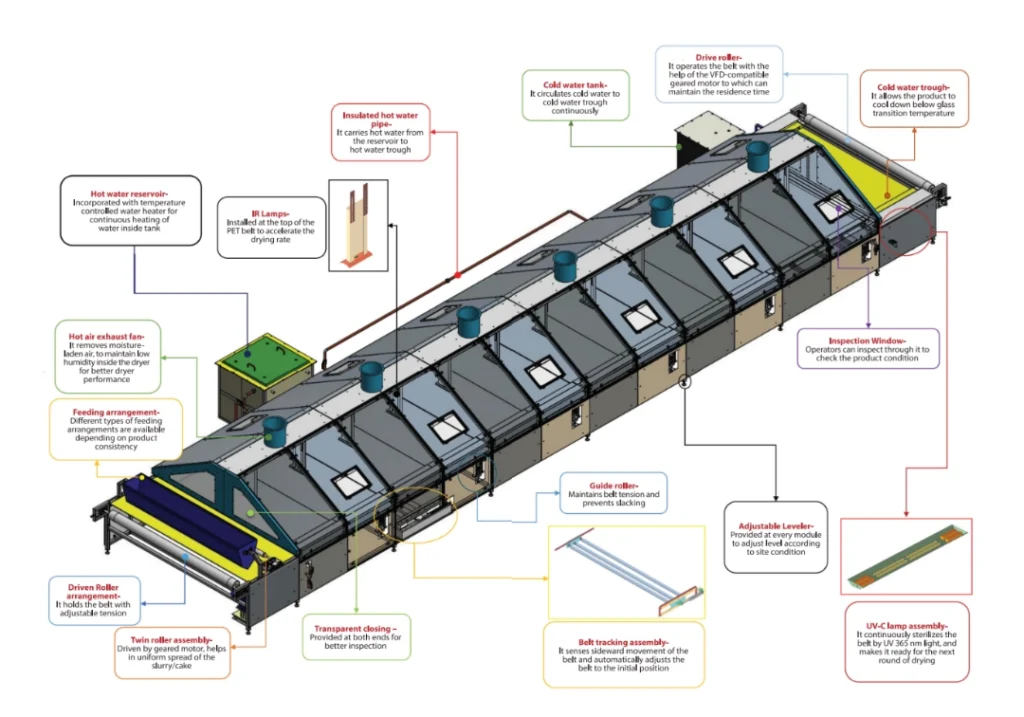

Salient Features

- IR lamps to accelerate the drying rate

- Transparent closing at both ends for better inspection

- UV-C lamp assembly for continuous sterilization

- Cold water trough to cool down product below glass transition temperature

- Hot air exhaust fan for removing the moist air

Advantages

- Preservation of Nutrients and Quality: The refractance window dryer uses a combination of infrared radiation and convective heat to dry materials. This method minimizes the exposure to high temperatures, which helps in preserving the nutritional content, flavour, and colour of the dried product.

- Uniform Drying: The technology provides uniform drying across the product by using a continuous flow of infrared heat. This ensures that the entire product is dried evenly, reducing the likelihood of over-drying or under-drying.

- Reduced Drying Time: Compared to some other drying methods, refractance window drying can be more efficient and faster. The combination of infrared radiation and hot air results in quicker moisture removal, which can be advantageous for large-scale production.

- Energy Efficiency: This drying process is often more energy-efficient than traditional methods. The use of infrared radiation allows for direct and efficient heating, which can reduce overall energy consumption.

- Lower Operating Cost: With reduced energy consumption and faster drying times, operating costs can be lower compared to other drying technologies. This is especially beneficial for large-scale operations.

- Eco-friendly:Environmental friendly due to minimal exhaust dust generation.

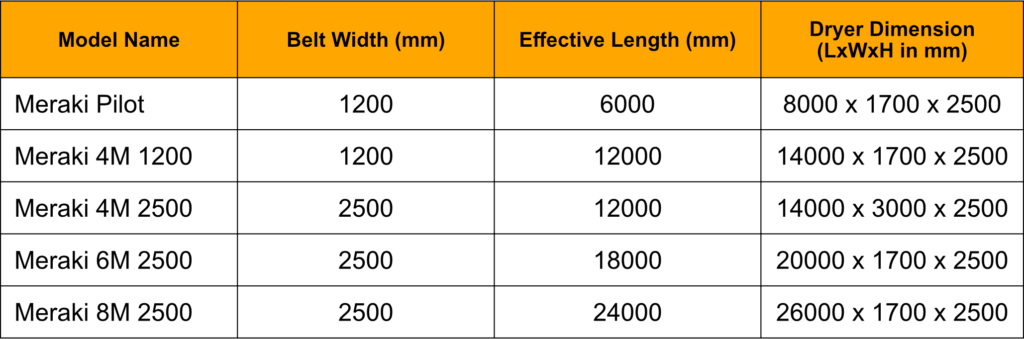

Variants of Continuous Thin Film Dryer

Specifications

- Maximum product temperature during drying is 70°C

- Retains 94% of Vitamin C & essential bioactivities

- Retention time of 10-15 min

- Modes of drying are Conduction, Convection & Radiation

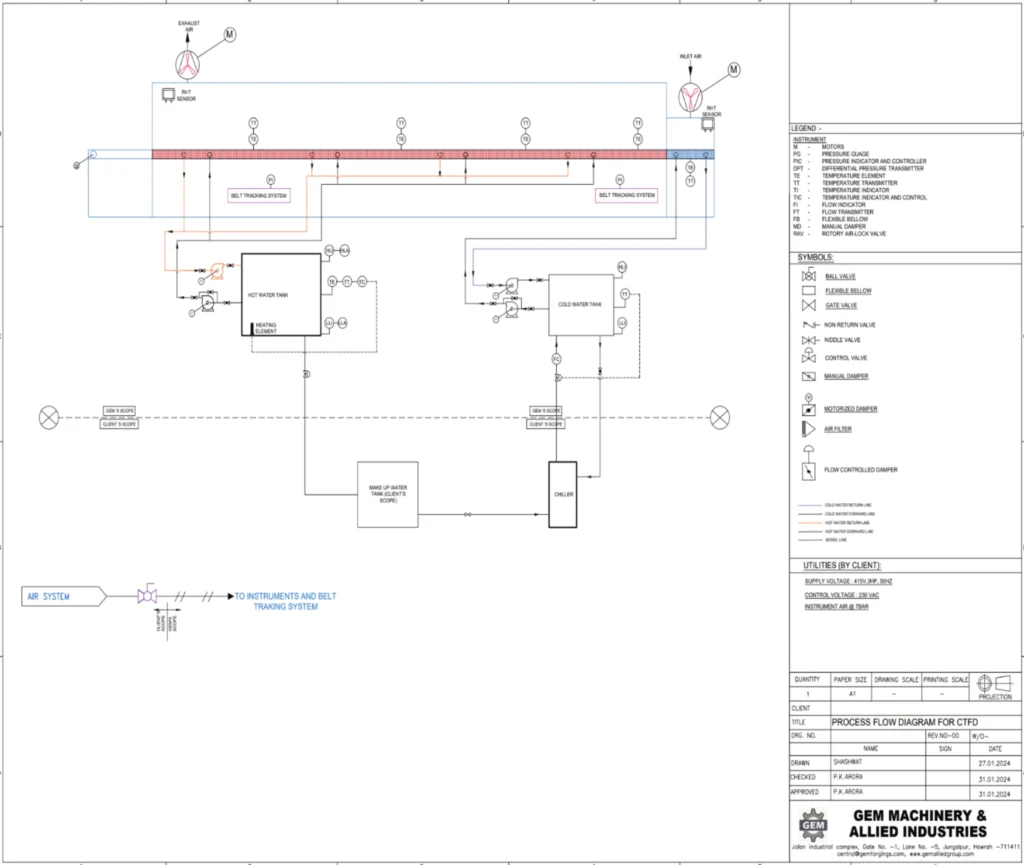

Process Flow Diagram

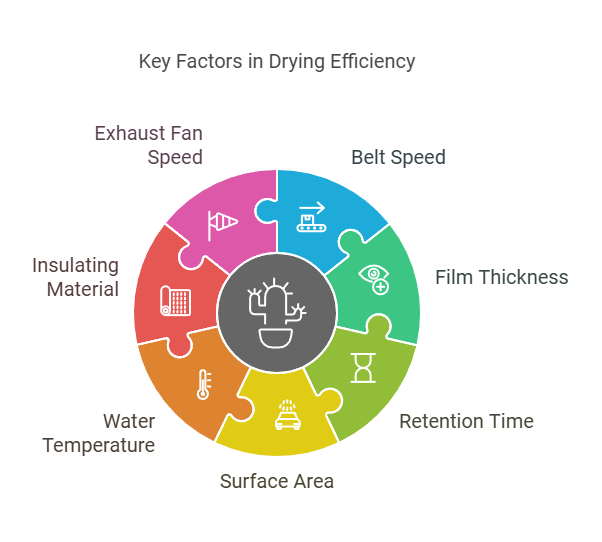

Factors Affecting Drying Rate

Application

Pharmaceutical

Neutraceutical

Spices

Fish and Meat Puree

Milk and Diary Product

Fruit Juice Concentrate

Have Questions ?