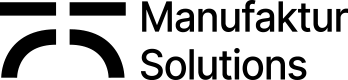

Conductive Fluidized Bed

Dryer

Conductive fluidized bed dryer is a very efficient solution for powdered and delicate products.

A Versatile Industrial Drying Technology

A Versatile Industrial Drying Technology

A Conductive fluidized bed dryer (CTFBD) uses conduction and convection to transfer heat to a material being dried, which helps maintain product quality and uniformity.

Working Principle of a Conductive Fluidized Bed Dryer

Submerged heating panels into the fluidized power make the design unique because of its highly effective method of transferring the heat from the panels to the powder through the fluidizing gas.

Material is fed into the internal heated Fluidized Bed Dryer receiving zone section and fluidized in the built-in heat exchanger area under the action of hot air. Hot air is incorporated in the heat exchanger. Materials are discharged through the discharge port after drying and enter the next process. Dust with hot air collected by cyclone separator. The exhaust gas is finally collected by a bag filter.

Salient Features

- Dual Heat Transfer Mechanism

- Enhanced Thermal Efficiency

- Compact design and smaller footprint

- Superior Product Quality Control

- Versatile Application Range

- Process Optimization Features

Advantages

- Exceptional Versatility: Capable of processing a wide variety of bulk solid materials

- High Efficiency: Removes large volumes of moisture quickly and consistently

- Robust Design: Withstands challenging industrial environments

- Adaptable Processing: Handles materials with varying moisture content and physical characteristics

- Minimal Product Degradation: Gentle tumbling action prevents material clumping and maintains product quality

Specifications

- Utilizes both conductive as well as convective heat transfer rate for faster drying.

- The dryer consists of embedded tube exchanger which has been inserted from the sides.

- Highly compact design due to reduction in hot air volume.

- As much as 80% of the thermal energy needed is delivered indirectly by the heating tubes.

- Continuous separation and discharging of bulky particles from the dryer.

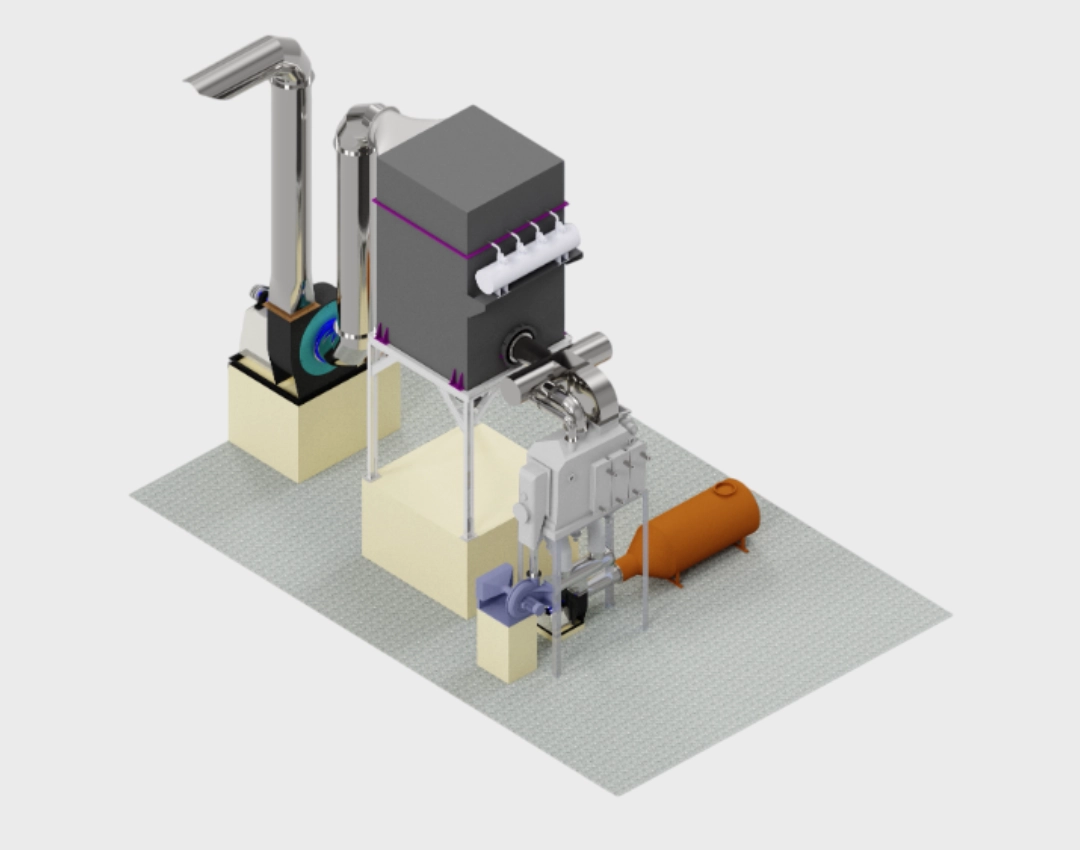

Process Flow Diagram

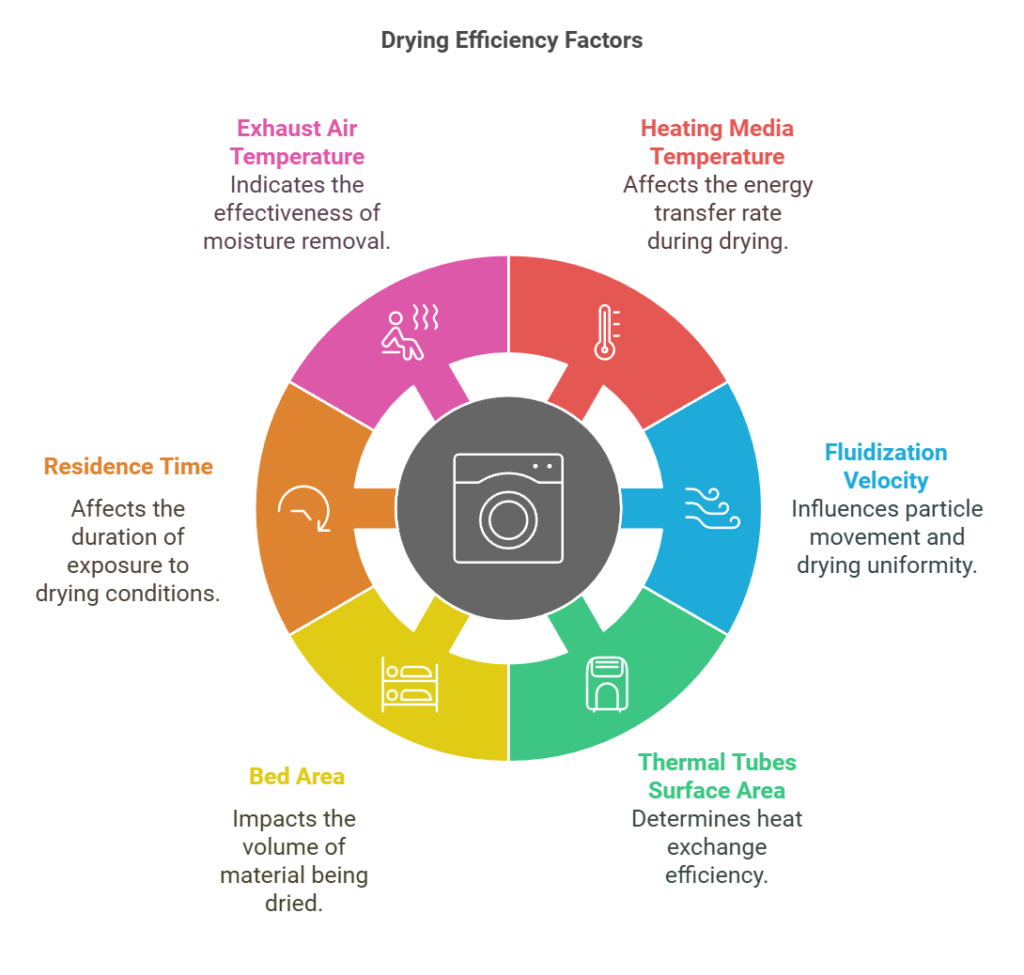

Factors Affecting Drying Efficiency

Applications

Synthetic Resin

Chemicals

Fertilizers

Feed

Agro-Chemicals

Pigment

Have Questions ?